Description

Image Gallery

Description

The Arc Pro Ultra V3 CNC Plasma Cutting Table is engineered for serious fabricators who want the perfect balance of precision, durability, and ease of use. Built on a rugged steel frame with premium NEMA 34 motors, planetary gearboxes, ball screw drive, and advanced motion control, the V3 delivers smooth, accurate cuts every time.

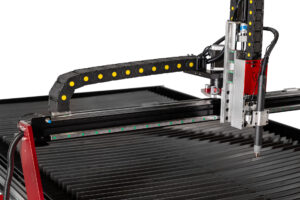

This system comes with more standard features than any other table in its class, giving you more value right out of the box. From robust cable management to advanced torch height control, it’s designed to keep your shop running efficiently. On top of that, the Ultra V3 also offers the widest range of options and accessories—including collision detection, plate engraver, rotary tube cutter, router, and laser add-ons—so you can expand capabilities as your work demands.

Powered by intuitive Arc CNC software, the Ultra V3 makes it easy to go from design to cut, whether you’re just starting out or running high-volume production. Available in multiple sizes to fit your workflow, every table is backed by the industry’s longest warranty, U.S.-based CNC plasma experts, and fast shipping from our Oregon and Illinois hubs.

The Arc Pro Ultra V3 isn’t just a machine—it’s the CNC plasma cutting table designed to grow with your shop.

Trusted By

Standard Performance Features

Click the red dots to explore features. Arc Pro Ultra V3 5×10 Shown.

Easy to Use ARC CNC Software

Ultra Precision Dual-Drive Gantry

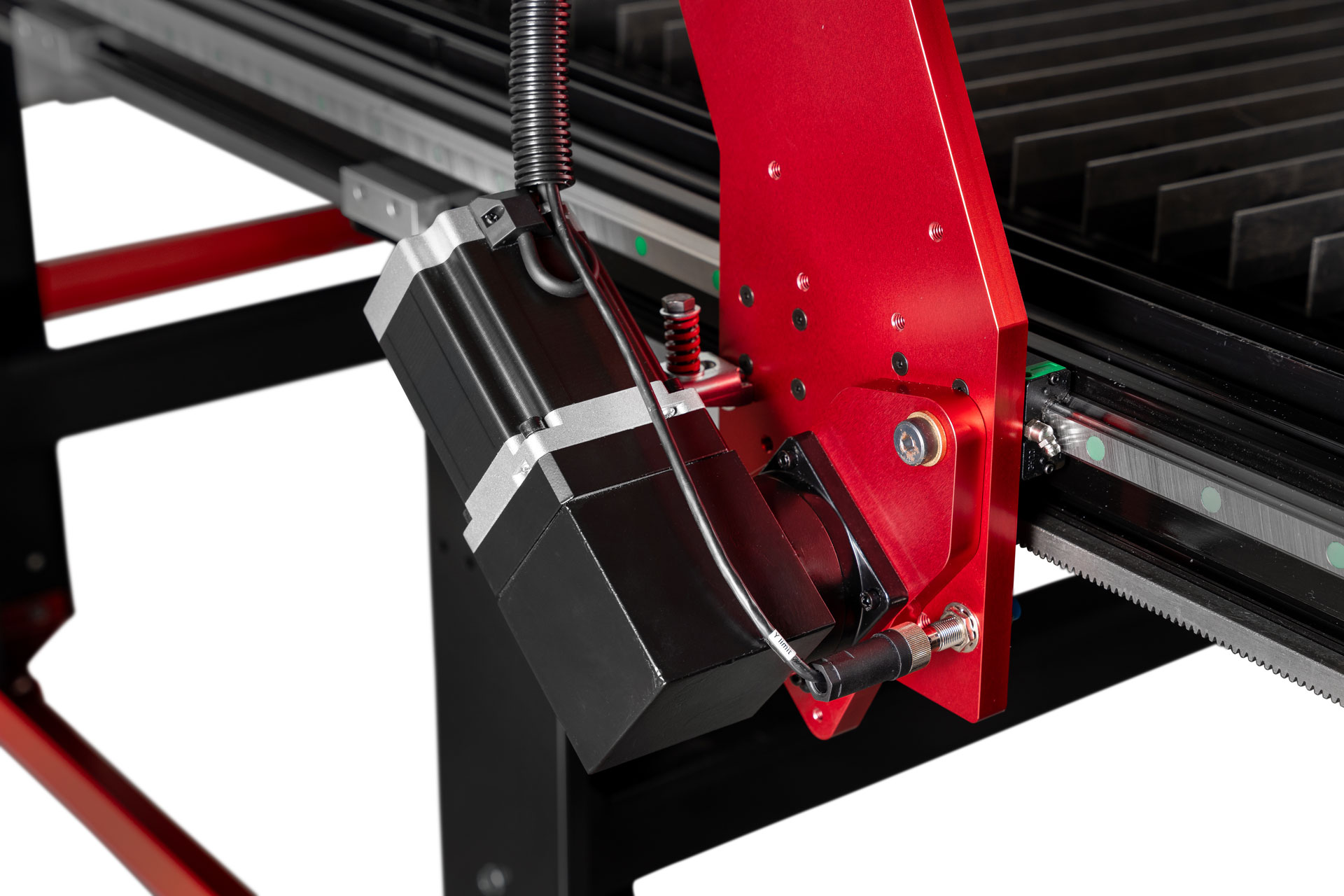

Planetary Gear Boxes

NEMA 34 Motors

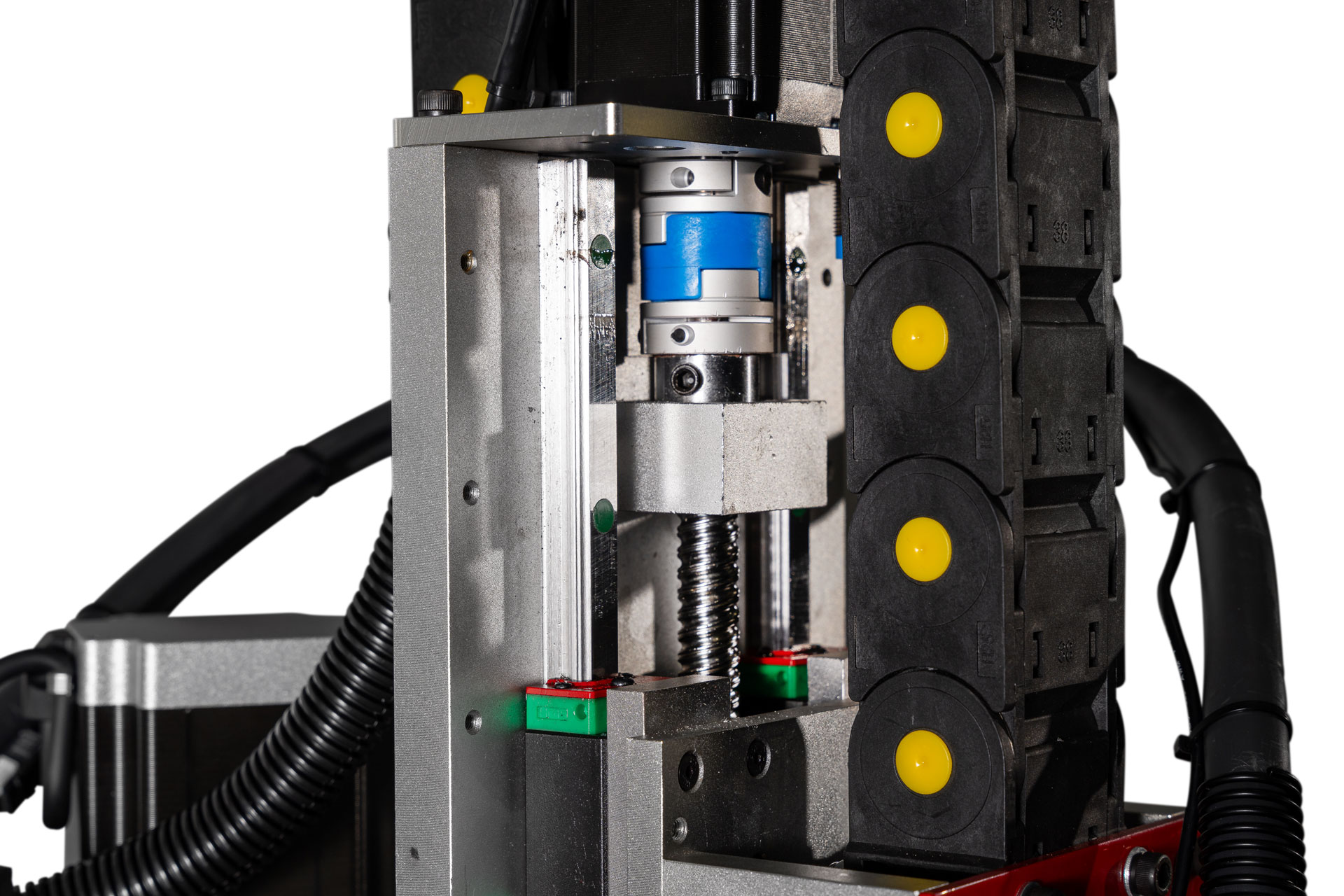

Ball Screw Z-Axis

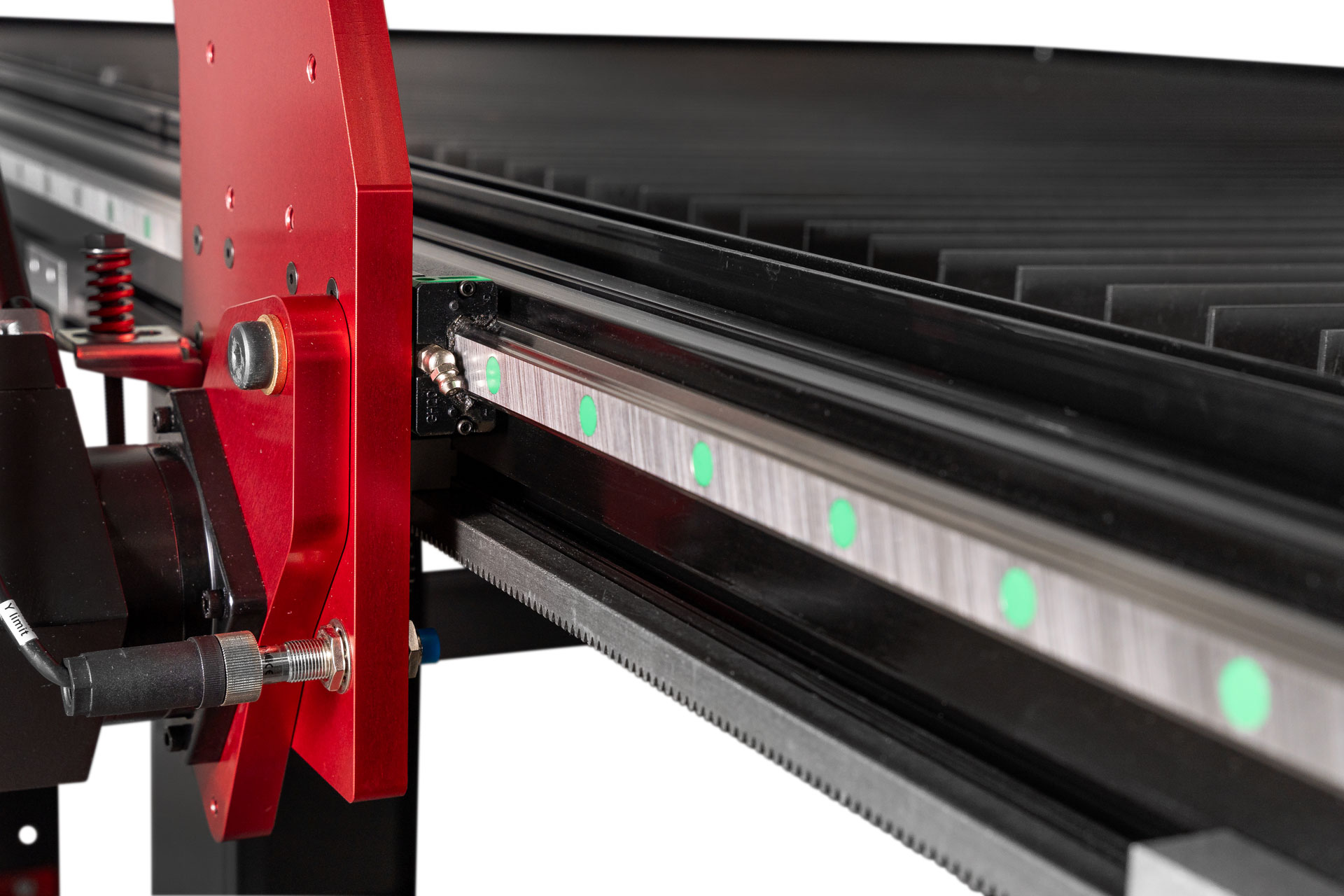

Hiwin® Precision Linear Rails

Precision Steel Frame

Advanced Control Systems

Leveling Rollers

Water Table

Enclosed Wiring

All new software designed for the Arc Pro Ultra series tables. Features:

- Modern, Upgraded Interface

- Intuitive Layout and Design

- Feature Packed Software. Packed with options and advanced capabilities.

- Easy Error Recovery

- Fast Forward and Rewind on Cut Path

- Add lead-in to resume cutting quickly

- Tool Adjustment On the Fly – Dial in Cut Speed, Cut Quality, Cut Height, Torch Volts

- Auto Rip Cut – for fast remnant cutoff.

- Start Point Recovery on Power Down – Pickup where you left off quickly

- Set Plate-Skew angle: Adjust alignment without having to move plate.

- Run Laser on Cut Path for Dry Running.

- Fixture Positioning: Set custom start points for jigs, materials and recurring jobs.

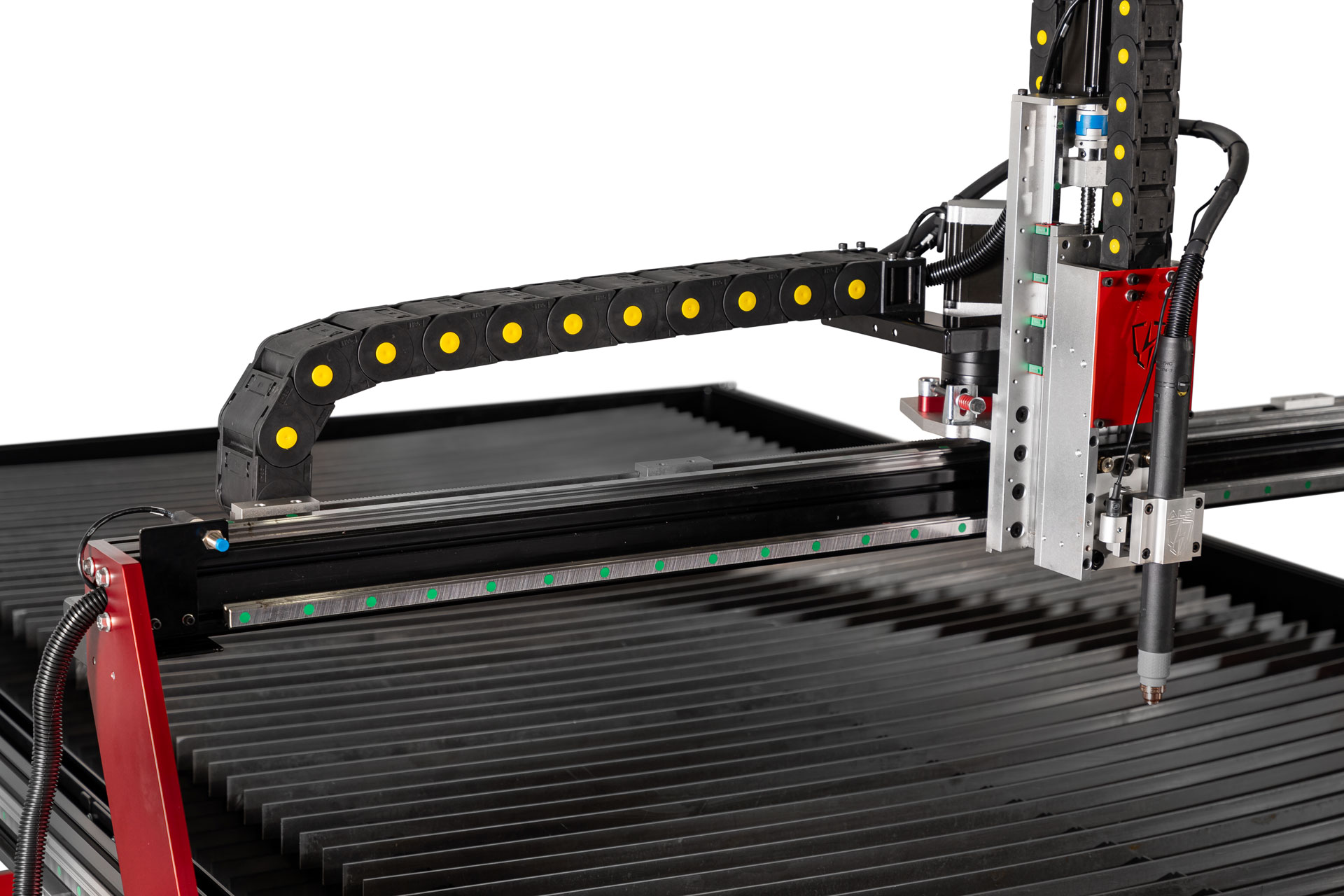

The Arc Pro Ultra V3 features a dual-drive gantry system engineered for unmatched speed and accuracy. Built with ultra-light, machined aluminum risers, the gantry reduces weight without sacrificing strength—delivering smoother motion and faster acceleration for high-speed plasma cutting.

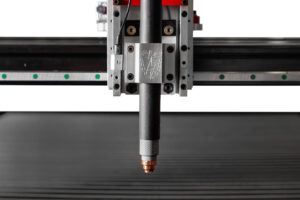

Powered by NEMA 34 motors, planetary gear boxes, and a ball screw Z-axis, the V3 achieves the highest clearance in its class and the most precise torch control available. The result: cleaner edges, tighter tolerances, and the confidence to take on complex jobs with maximum efficiency.

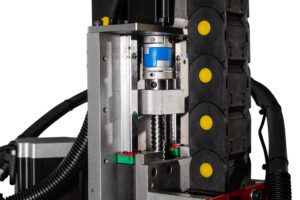

The Arc Pro Ultra V3 is equipped with precision planetary gear boxes that deliver maximum torque and accuracy with every cut. Their compact, rugged design ensures smooth motion, reduced backlash, and long-term reliability under heavy shop use. By evenly distributing load across multiple gears, planetary gear boxes provide the strength and precision needed for demanding CNC plasma cutting applications.

Built with powerful NEMA 34 motors, the V3 delivers the speed, consistency, and responsiveness fabricators depend on. These industrial-grade stepper motors provide precise positioning and reliable motion control, ensuring clean, accurate cuts across the entire table. With their proven durability and high torque output, NEMA 34 motors are the backbone of the Ultra V3’s performance.

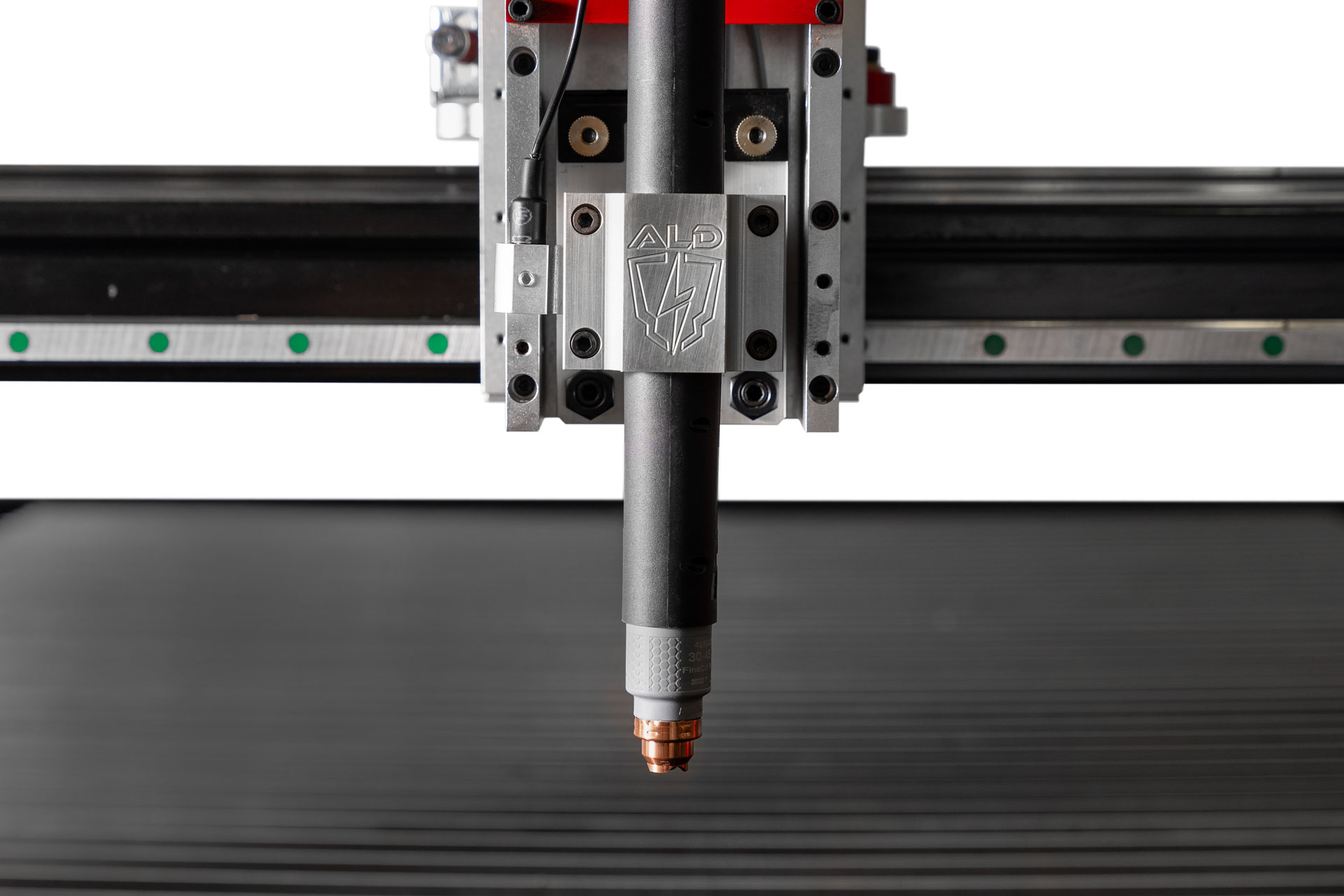

The Arc Pro Ultra V3 uses a precision ball screw Z-axis for smooth, reliable vertical motion. This design virtually eliminates backlash while delivering consistent torch positioning and repeatability. Built for durability under heavy use, the ball screw system provides tighter tolerances, longer life, and more accurate pierces and cuts compared to standard lead screw designs.

- Hiwin® 20 mm precision linear guide rails

- Provides super smooth motion for unmatched cut quality

- Dual seals and scrapers maintain a clean guideway for longer life and the best protection available

The Arc Pro Ultra V3 CNC Plasma Table by Arclight Dynamics features a precision-engineered steel frame that ensures exceptional stability and durability. This robust construction minimizes vibrations, allowing for smoother and more accurate cuts with tighter tolerances. Experience the precision and reliability of the Arc Pro Ultra’s steel frame, delivering professional-grade results with every cut.

With advanced features like corner and hole slow downs, reverse cut directions, contouring, and additional option inputs, you will achieve superior cut quality through simple programming that is easy to understand and use.

The Arclight Plasma system allows for complete control of the cut: pause, fast forward, rewind and re-cut any part, virtually eliminating steel/materials waste. Our Computer Numerated Control (CNC) system provides a simple ‘click of the button’ control and operation or can operate with complex sophistication using personally generated g-code. CNC features that our competitors just don’t offer.

- Preloaded with Hypertherm cut charts and toolsets

- Ethernet based communications, for more reliable faster performance.

- Industrial Linux software for reliability and ease of use

- Torch Height Control with blazing fast response

- Dynamic Voltage Sampling

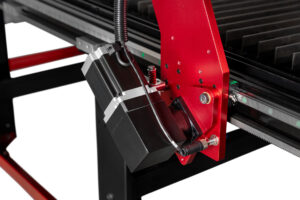

All-in-one leveling rollers are standard equipment with the Arc Pro Ultra V3 CNC Plasma Table. Move your table and level it with ease.

Specifications

For the Arc Pro Ultra V3 4×8 CNC Plasma Table

- Cutting envelope: 51.5" x 104" x 6"

- Overall dimensions: 163” x 58” x 67”

- Weight capacity: 1.5" Thick Mild Steel

- Frame: Steel

- Dimensions at base: 72” x 120”

- Water pan capacity: 107 Gallons

- Table Power: 110V / 15-20A

- Overall Weight: 1,015 pounds

- Positioning Accuracy: .001"

Learn More

Learn more about how Classic Car Studios uses their Arclight Dynamics CNC Plasma Table.

See how Barbie the Welder uses her table to grow her business.

Jim Colt on the Advanced Machine Interface of the Arclight Dynamics CNC plasma tables.

Jim Colt speaks to the Voltage Sampling feature on Arclight Dynamics CNC Plasma Tables.

Support You Can Count On

When you choose Arclight Dynamics, you’re backed by a full team of U.S.-based CNC plasma experts—right here in Oregon. Our sole focus is keeping your table running and your shop productive. While other manufacturers leave customers waiting weeks for answers, our team delivers fast, reliable support that minimizes downtime and protects your bottom line. With Arclight, you’re never on your own.

Special Offer

Financing Available

$99 for the first 6 months

Explore financing options and get started growing your business with a new Arclight Dynamics CNC Plasma Table.

ArcLight Dynamics Guarantee

We offer a worry-free 30-day customer satisfaction guarantee on all of our tables. Our aim is to ensure that all of our products are manufactured with the highest quality and standards.